Aka-Brief

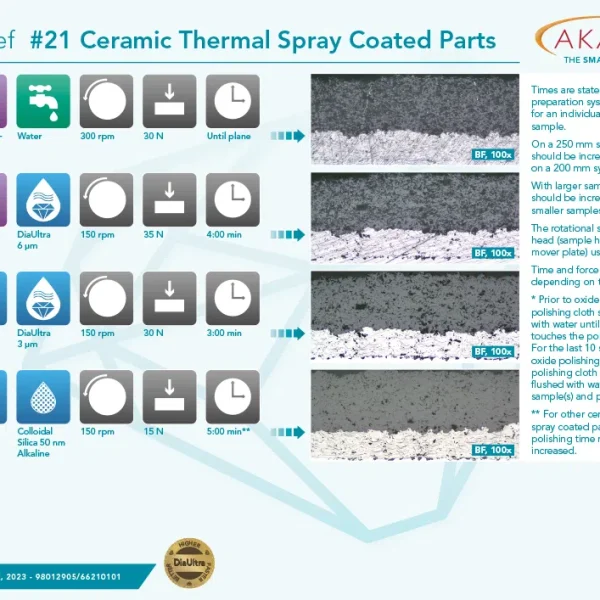

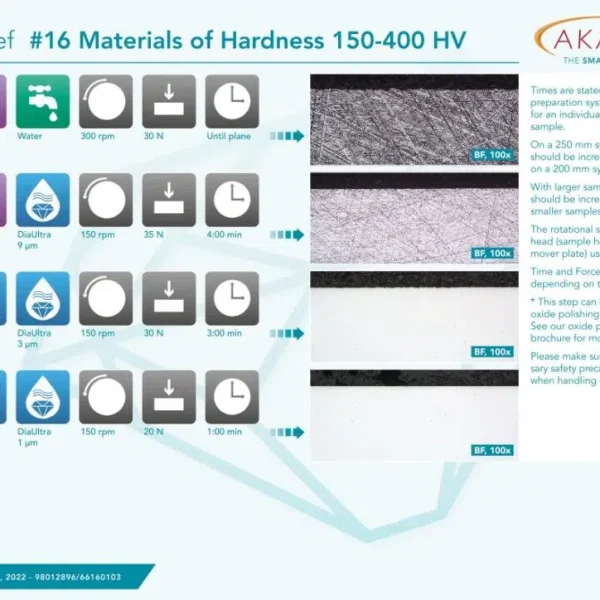

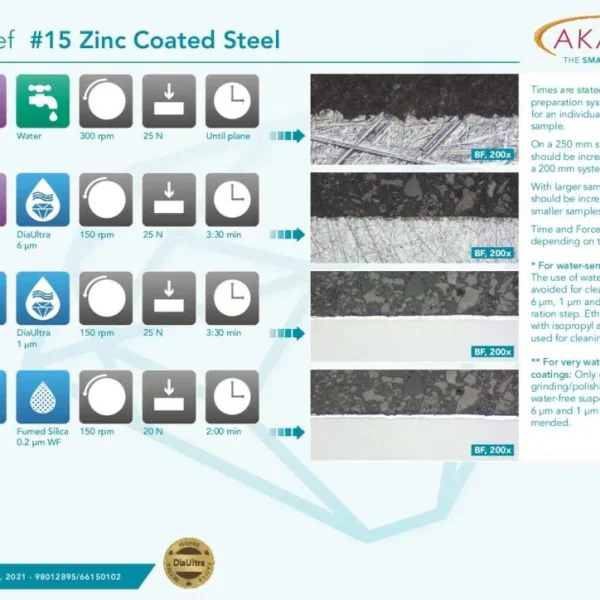

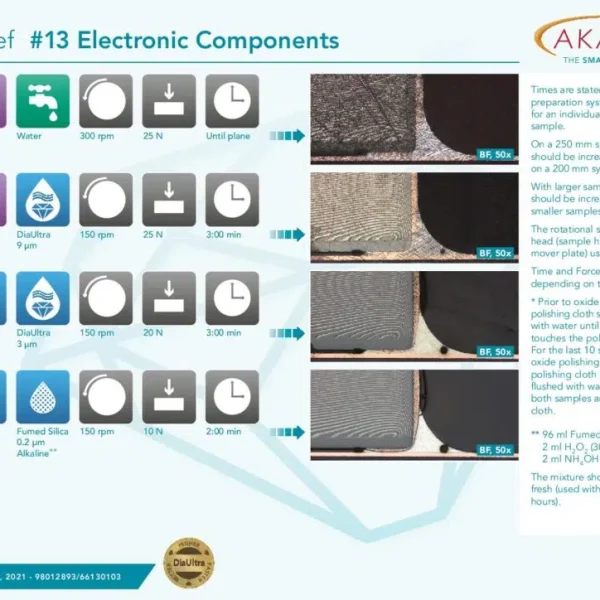

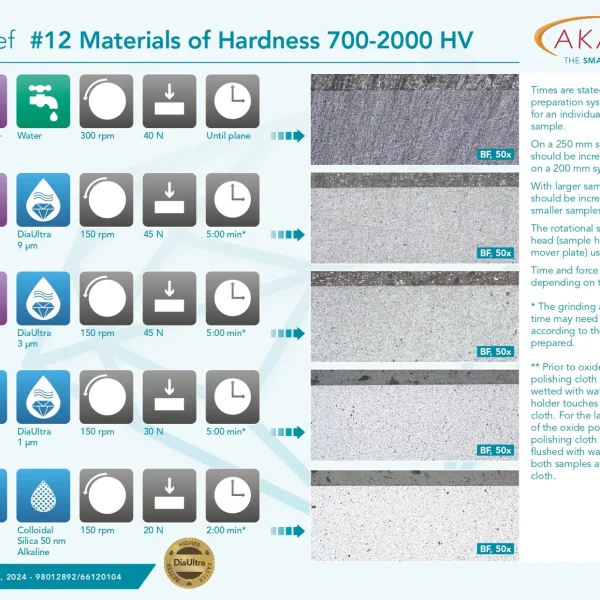

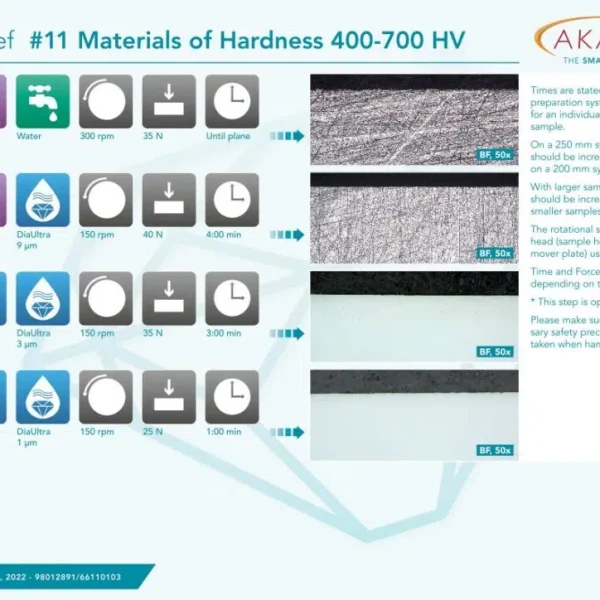

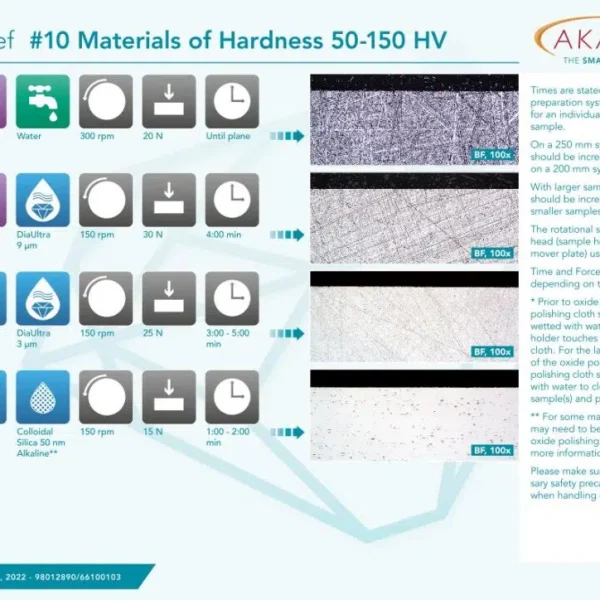

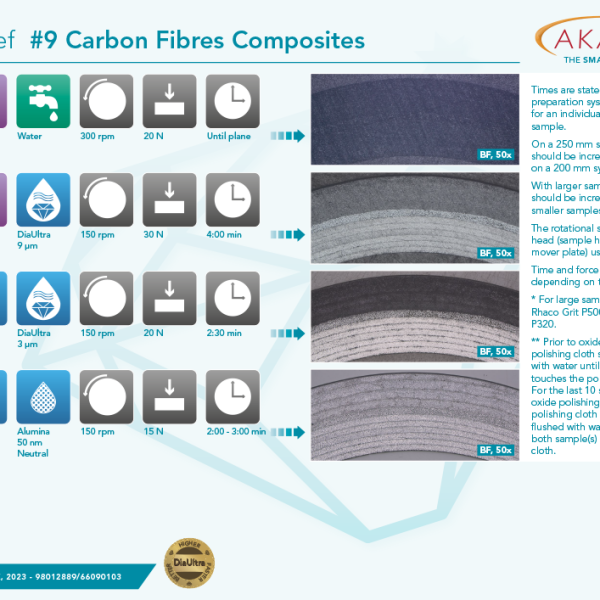

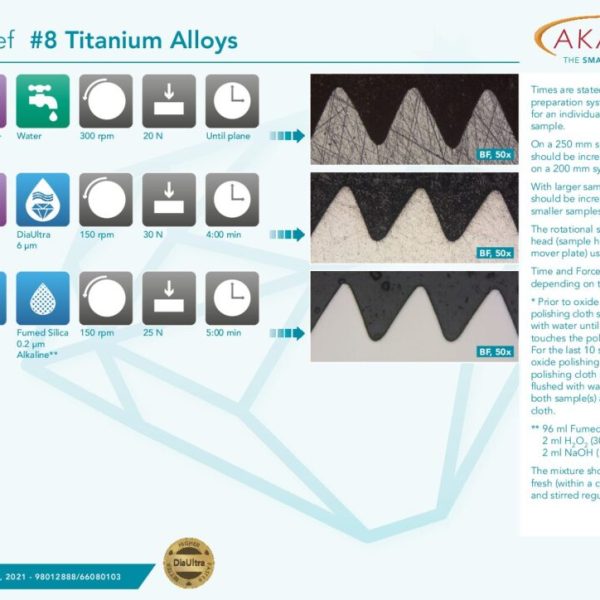

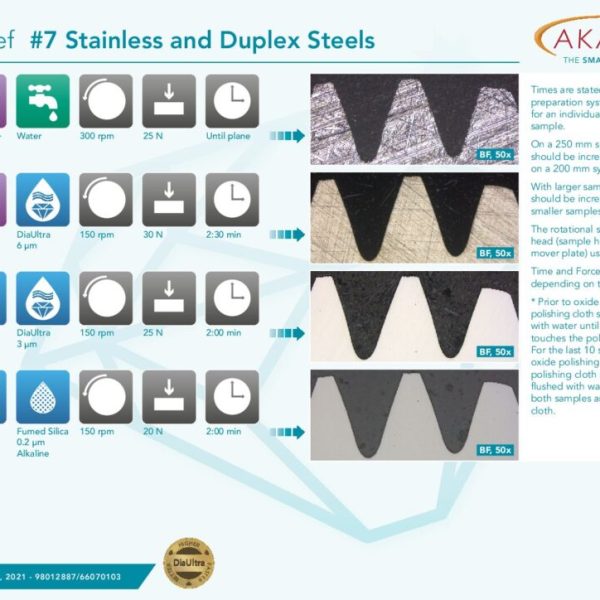

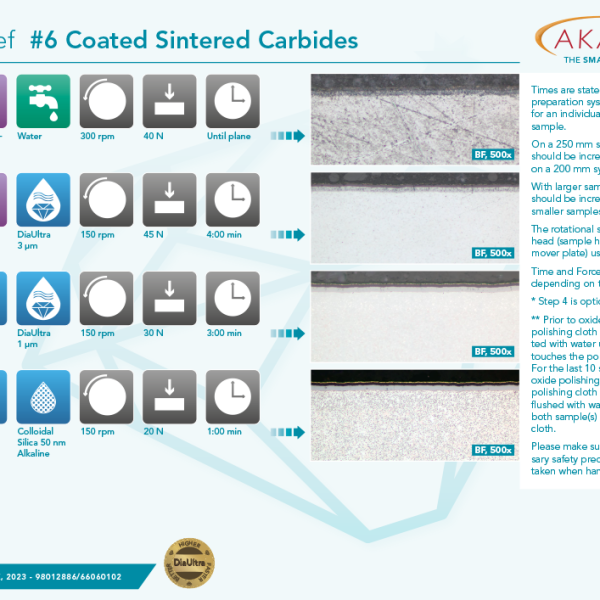

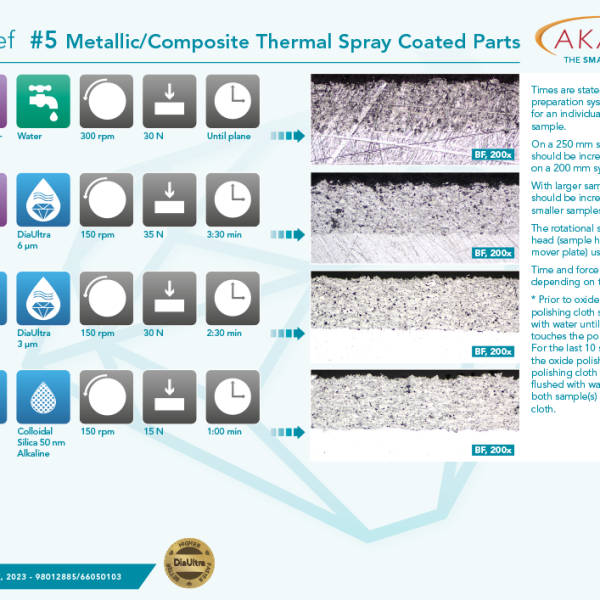

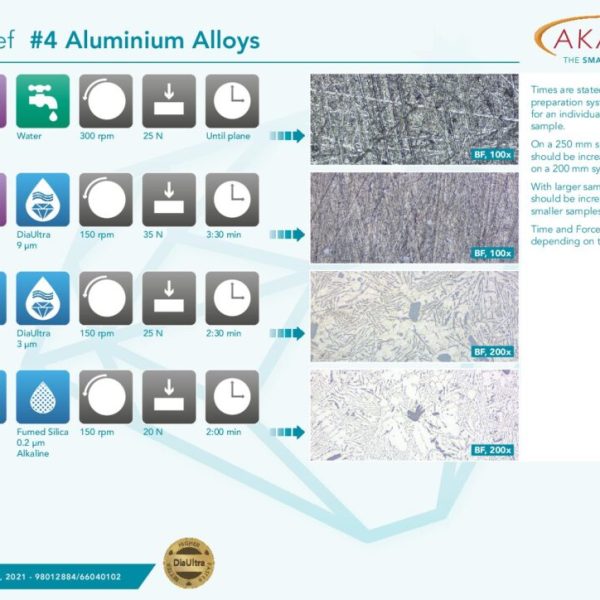

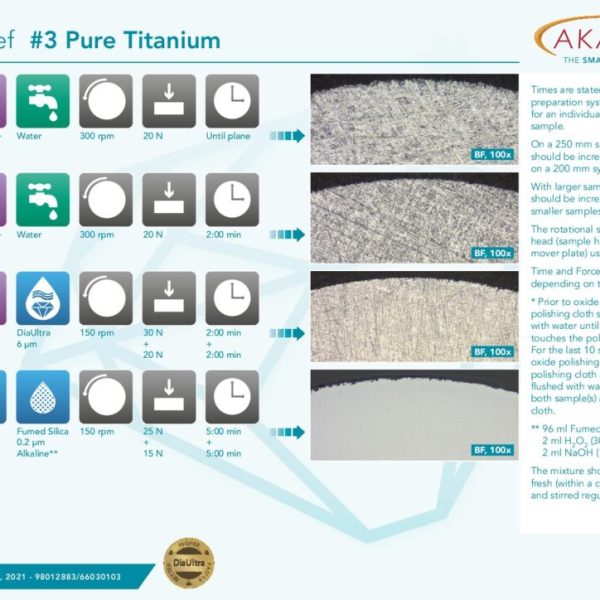

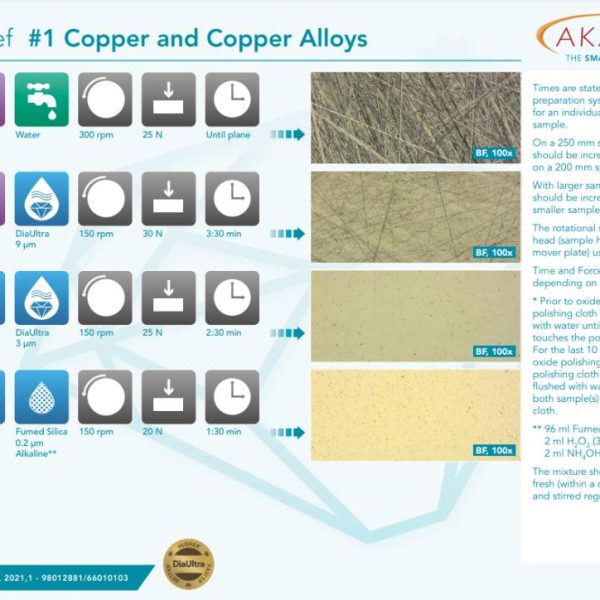

In addition, a micrograph is shown with the expected preparation result after each step.

This makes it possible for you to determine whether the individual steps have been successfully completed or if something needs to change.

There are two different types of preparation methods: Specific Methods for certain materials and General Methods for a range of materials based on their hardness. All methods are carefully optimised to provide the best possible quality at the lowest possible cost.

Click on a link below to view and download the Aka-Brief for a specific material or range of materials.

Showing all 21 resultsSorted by latest

-

Ceramic Thermal Spray Coated Parts

Get PDF -

Superalloys

Get PDF -

Superalloys with Diffusion Coatings

Get PDF -

Surface Hardened Steel

Get PDF -

Nitrided and Nitrocarburized Steels

Get PDF -

Materials of Hardness 150-400 HV Link

Get PDF -

Zinc Coated Steel Link

Get PDF -

Cast Iron Link

Get PDF -

Electronic Components

Get PDF -

Materials of Hardness 700-2000 HV

Get PDF -

Materials of Hardness 400-700 HV

Get PDF -

Materials of Hardness 50-150 HV Link

Get PDF -

Carbon Fibres Composites

Get PDF -

Titanium Alloys

Get PDF -

Stainless and Duplex Steels Link

Get PDF -

Coated Sintered Carbides Link

Get PDF -

Metallic/Composite Thermal Spray Coated Parts Link

Get PDF -

Aluminium Alloys Link

Get PDF -

Pure Titanium Link

Get PDF -

Multilayer Ceramic Capacitors (MLCC) Link

Get PDF -

Copper and Copper Alloys Link

Get PDF